Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

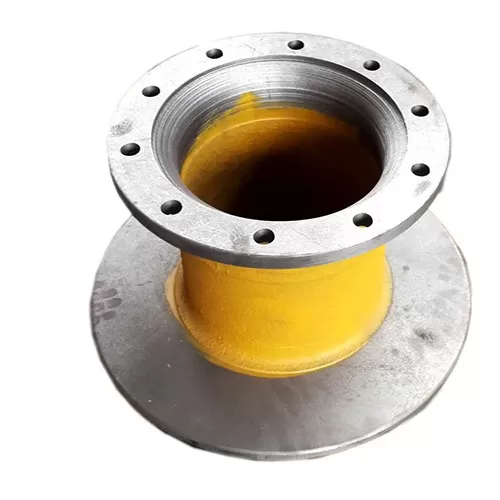

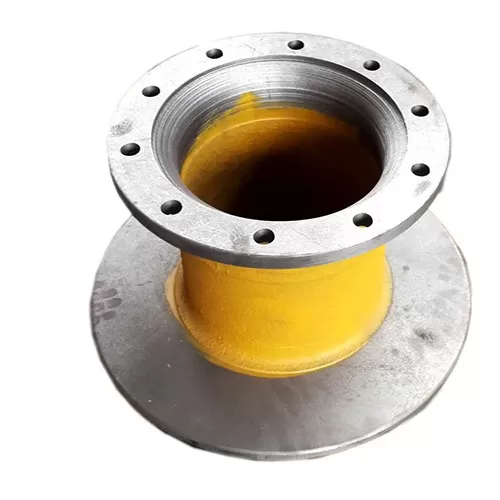

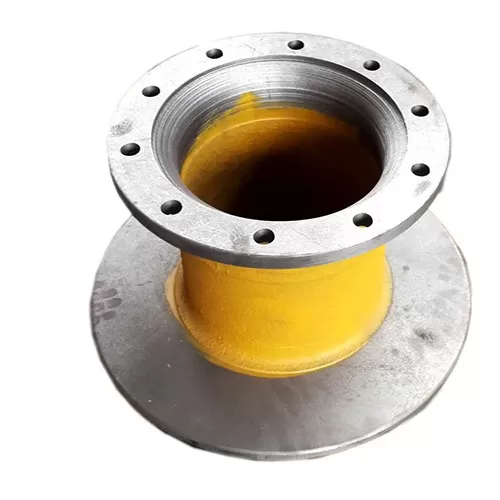

Model No.:250300297

Brand:CUMMINS

Warranty:3 Month

Certification:ISO

Condition:New

Rated Load:3-6t

Transmission:Hydraulic - Mechanical

Load and Unload Mode:Front Discharge

Walking Mode:Wheeled

Type:Medium-sized Loader

Packaging:box

Productivity:10000

Transportation:Ocean,Land,Air

Place of Origin:CHINA

Supply Ability:1000 Pc per day

Certificate:ISO

Port:Shanghai,Qingdao,Guangzhou

Payment Type:L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Disassembly and assembly of disc brake 1. Disassembly and assembly of brake disc Disassembly steps: 1) Lift and support the car safely and remove the front wheels. 2) Remove the Brake Caliper assembly and hang it aside. 3) Remove the slotted nut, coil spring and middle piece. Insert a lever into the middle gap and tap lightly to remove the middle piece. 4) Remove the wheel hub and brake disc assembly from the axle shaft by hand. installation steps: 1) Install the wheel hub and brake disc assembly on the axle shaft. Install the conical spring and slotted nut and tighten them temporarily to ensure that the conical spring is installed in the correct direction. 2) Install the brake caliper assembly and tighten the bolts according to the technical requirements. 3) Tighten the slotted nut with a torque of 145 lbf·ft (196N·m). Install the wheels and put down the car. [TOP] 2) Disassembly and assembly of disc brake friction block 1. Friction block of front disc brake caliper (Figure 12-1) Disassembly steps: 1) Lift and support the car safely. Remove the wheel assembly. 2) Release the parking brake and remove the control cable from the brake caliper lever. 3) Remove the lock pin bolt from the front and bottom of the brake caliper. 4) Turn the brake caliper on the bracket and swing it to the side and upward. 5) Remove the friction pad of the brake disc, pay attention to the position of the friction block and the friction block clamp. installation steps: 1) Check the brake disc, brake caliper and fixed components. If necessary, correct them. 2) Drain a small amount of brake fluid from the brake master Cylinder reservoir, use a suitable tool to screw the brake caliper piston clockwise into the brake master cylinder hole and correct the notch. Make sure that the dust cover is not twisted or pinched. Note: Do not force the piston directly into the main cylinder bore. The piston is fixed on a threaded mandrel, which bends under pressure. 3) Install a new friction block in the brake caliper to ensure that the shims and fixing clips are in place. 4) Swing the brake caliper down to reset it, install the lock pin bolt, and tighten the lock pin bolt according to the following technical requirements: ①The Gasti model is 16-23 lbf·ft (22-31N·m). ②The Legacy model is 33-40 lbf·ft (44-54N·m). ③The loyal model is 25-33 lbf·ft (34-44N·m). ④SVX model 25-33 lbf·ft (34-44N·m). 5) Reconnect the parking brake cable and add brake fluid. 6) Install the wheel assembly. Bleed the brakes, put down the car, and test the car on the road. 2. Disc type rear brake friction block (Figure 12-2) Disassembly steps: 1) Lift and support the car safely. Remove the wheel assembly. 2) If there is a brake friction pad wear indicator, disassemble it. If there is a damping spring and or a fixing clip, remove it. 3) Pull out the brake caliper from the middle of the car and press the piston into the brake caliper hole. Remove the brake caliper guide pin and remove the brake caliper from the brake disc. Hang the brake caliper with a sling. 4) Slide the friction block from the brake caliper. Pay attention to the gasket and cover behind the liner. Note: If the parking brake is installed, use a suitable tool to turn the piston into the brake caliper hole. If the parking brake is not installed, the piston can be directly pressed into the brake caliper hole. installation steps: 1) Push the piston into the brake caliper hole to install the pad, locate the washer or cover in place, and perform the reverse process of removal. 2) Tighten the lower brake caliper bolts according to the following torque: ①The Legacy model is 16-23 lbf·ft (22-31N·m). ②The loyal model is 12-17 lbf·ft (16-24N·m). ③SVX model 12-17 lbf·ft (16-24N·m) [TOP]

Product Categories : Home > Products > Transmission and converter System > Transmission Box

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.