Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.:612600130430

Brand:CUMMINS

Warranty:3 Month

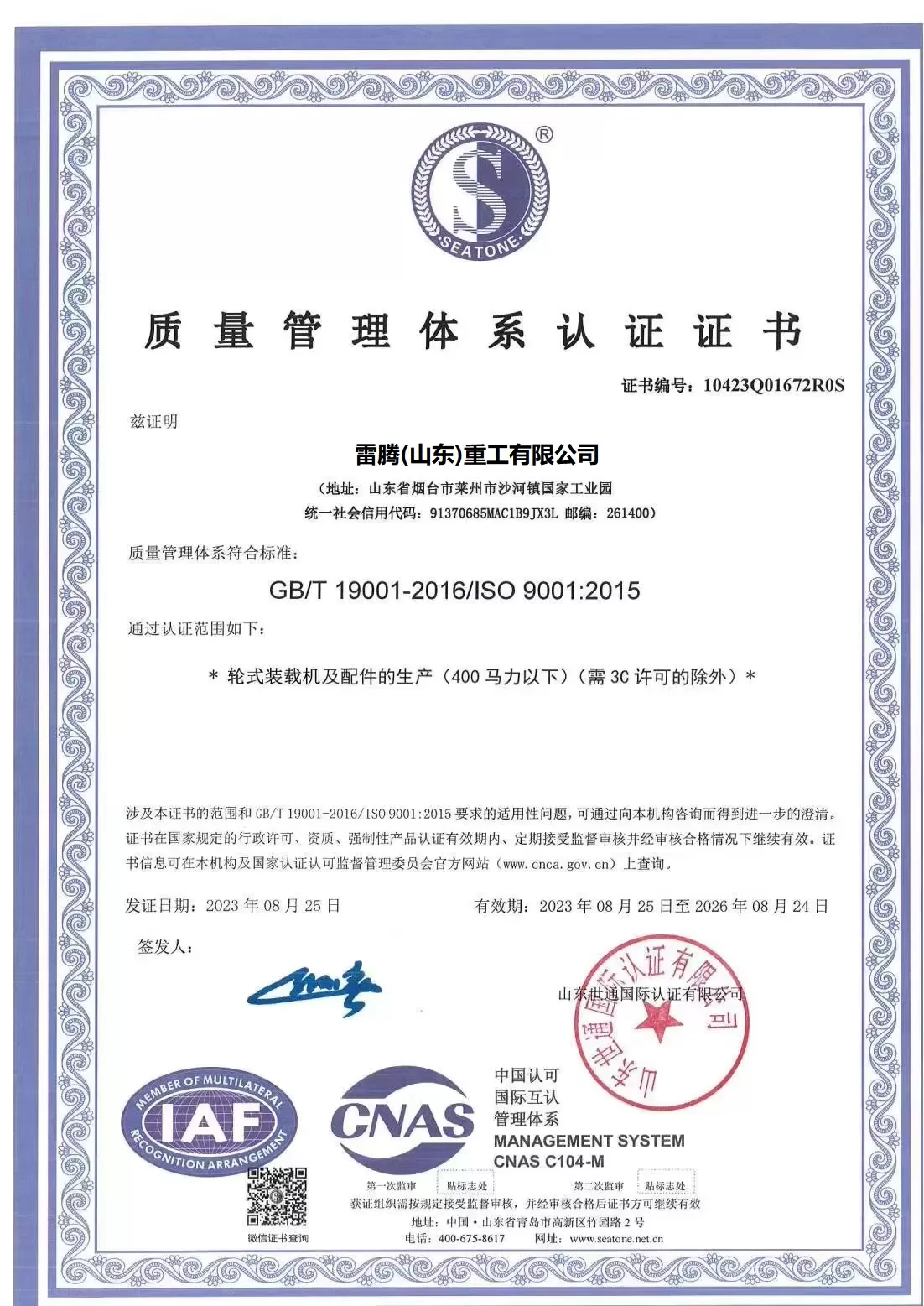

Certification:ISO

Condition:New

Rated Load:3-6t

Transmission:Hydraulic - Mechanical

Load and Unload Mode:Front Discharge

Walking Mode:Wheeled

Type:Medium-sized Loader

Packaging:box

Productivity:10000

Transportation:Ocean,Land,Air

Place of Origin:CHINA

Supply Ability:1000 Pc per day

Certificate:ISO

Port:Shanghai,Qingdao,Guangzhou

Payment Type:L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

9 common faults and solutions of air compressors 1. The air compressor suddenly stops during operation The reasons are: (1) The suction pressure is too low, which is lower than the low pressure lower limit of the pressure relay; (2) Exhaust pressure is too high, causing the high-voltage relay to operate and power off; (3) The oil pressure is too low, and the oil pressure relay acts as a relay; (4) Motor overload, thermal relay action relay; elimination method: (1) Check the reason. If the pipeline is blocked, the pipeline should be unblocked. If the system refrigerant is insufficient, add it; (2) Check the cooling capacity or cooling air volume of the condenser; (3) Check the pipelines and pumps of the oil delivery system; (4) Check whether the power supply voltage is low or the cooling load is too large; 2. Exhaust gas compression is too high The reasons are: (1) The cooling water volume of the water-cooled condenser is insufficient or the cooling air volume of the air-cooled condenser is insufficient; (2) The surface of the condenser tube cluster is too thick or oily, which causes difficulty in heat dissipation; (3) There is air in the refrigeration system; (4) Overfilling of refrigerant; (5) The valve in the exhaust pipe fails, causing the pressure to be too high; elimination method: (1) Check whether the valve is fully open, increase the water supply or check the motor voltage, speed, and whether the transmission belt is too loose; (2) Clean the scale and brush the oil stains to make the surface of the condenser tube clusters clean; (3) let out the air; (4) Exhaust excess refrigerant; (5) Check and correct the valve; 3. Causes the wet stroke of the air compressor The reasons are: (1) The thermal expansion valve fails and the opening is too large; (2) The solenoid valve fails, a large amount of refrigerant enters the evaporation pipe after the shutdown, and enters the air compressor when it is turned on again; (3) The system is filled with too much refrigerant; (4) The temperature sensing bulb of the thermal expansion valve is loose and not tied, causing the opening of the thermal expansion valve to increase; elimination method: (1) Close the liquid supply valve and overhaul the thermal expansion valve; (2) Overhaul the solenoid valve; (3) release excess refrigerant; (4) Check the binding of the temperature Sensor bag; 4. The air compressor is stuck The reasons are: (1) There are dirty impurities in the lubricating oil; (2) The oil pipe of the oil pump is blocked, causing the Cylinder to run out of oil and the piston is stuck; (3) The shank pin of the main gear of the oil pump inserted into the crank is twisted, causing the oil system to cut off; elimination method: (1) Replace with new lubricant; (2) Repair the oil pump pipeline; (3) Repair and replace the main gear shaft of the oil pump; 5. There is a strange sound in the cylinder The reasons are: (1) The dead center clearance in the cylinder is too small; (2) The clearance between the piston pin and the connecting rod bushing is too large; (3) The valve plate is broken; (4) The sound of oil hitting caused by the crankshaft crank or the big end of the connecting rod; elimination method: (1) Adjust the thickened cylinder gasket; (2) Replace the piston pin or bushing; (3) Shut down immediately to replace the valve; (4) It is not necessary to shut down for a short time, such as stopping for inspection after a few minutes; 6. There is sound in the crankcase The reasons are: (1) The connecting rod nut is loose; (2) The gap between the connecting rod and the bearing bush is too large; elimination method: (1) Stop and re-tighten; (2) Replace the tiles; 7. The air compressor does not start The reasons are: (1) The fuse is in poor contact or blown out when the power is off; (2) Poor contact of the vertical contact point of the starter; (3) The temperature controller is out of adjustment or malfunctions; (4) The adjustment of the pressure relay is not suitable; elimination method: (1) Check the power supply and fuse; (2) Check the starter and clean the contacts with gauze; (3) Check the temperature indication position and check the various components; (4) Check the components or setting values of the pressure relay; 8. The air compressor has insufficient cooling capacity The reasons are: The piston ring is worn or the gap between the piston and the cylinder is too large due to wear; elimination method: Replace with new piston ring or overhaul with new parts; 9. There is noise in the air compressor and motor coupling The reasons are: (1) The air compressor and the motor coupling are not properly matched; (2) The key and the keyway of the coupling are not properly matched; (3) The elastic ring of the coupling is loose or damaged; (4) The belt is too loose; (5) The inner hole of the coupling and the shaft fit loosely; elimination method: (1) Reassemble according to the correct assembly requirements; (2) Adjust the fit of the key and the keyway, change the key; (3) Fasten the elastic ring or replace it with a new one; (4) Adjust and tighten the belt; (5) Adjust and tighten the coupling;

Product Categories : Home > Products > Engine System > Weichai Engine Spare Parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.