Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.:22t-36t

Brand:HL

Type:Crawler Excavator

Usage:Mining Excavator

Bucket:Grab Shovel

Transmission:Hydraulic Transmission

Drive Type:Internal Combustion Drive

Bucket Capacity:1.0~1.5m³

Size:Medium-Sized

Condition:New

Packaging:Ro-ro ship

Productivity:10000

Transportation:Ocean

Place of Origin:CHINA

Supply Ability:100 unit per day

Port:Shanghai,Qingdao,Guangzhou

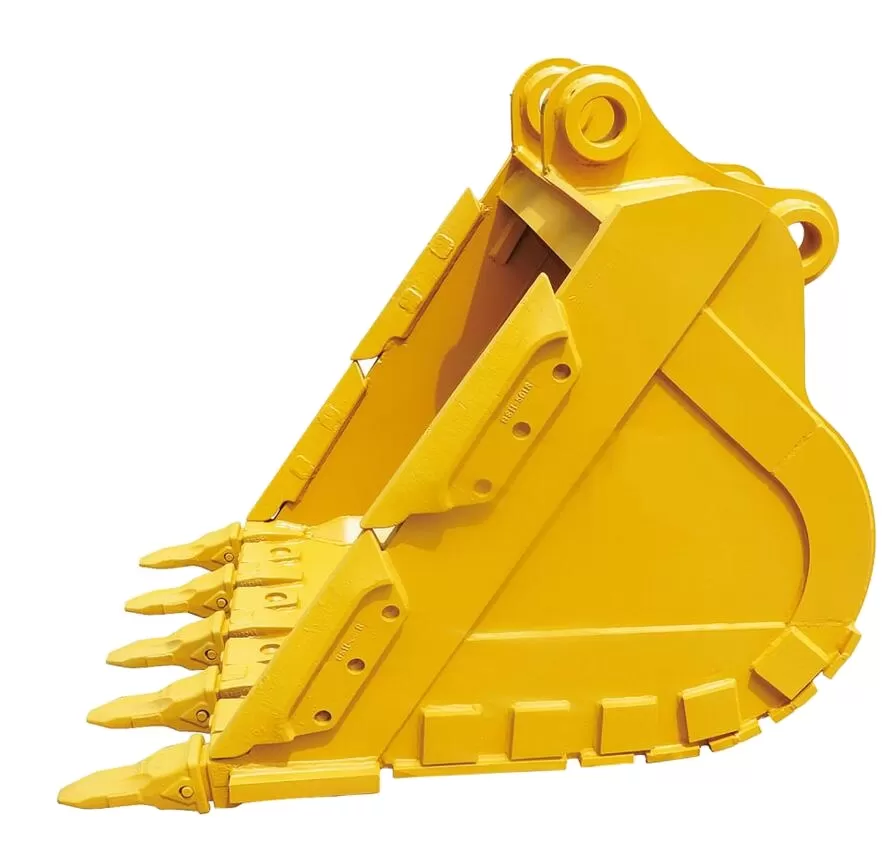

Bucket refers to the bucket installed on the excavator, also known as the bucket. According to the working mode, it is divided into back bucket and front bucket. Generally, backhoe buckets are commonly used. Divided by material: standard bucket, reinforced bucket and rock bucket.

Bucket structure Bucket is a kind of structural product, consisting of tooth seat plate, bottom plate, side plate, wall plate, ear plate, back plate, bucket ear plate, bucket ear cover, bucket Teeth, tooth seat, guard plate or bucket angle It is composed of other parts, therefore, welding is the most critical manufacturing process for the bucket. The welding quality directly affects the structural strength and service life of the bucket.

Bucket replacement

The bucket is connected to the stick and connecting rod through the stick pin and the connecting rod pin, as shown in the right picture. To replace the bucket, actually first remove the stick pin and the Cylinder pin of the connecting rod bucket, remove the original bucket, and then use the stick pin and connecting rod pin together with the stick for other buckets or working devices. Connecting with the connecting rod is the process of installing the arm pin and the connecting rod pin.

The steps to replace the bucket are as follows: (1) Place the bucket on a flat ground. In the process of lowering the bucket, make the bucket just touch the ground to minimize the resistance when removing the pin. (2) Remove the rocker pin and connecting rod pin. Remove the double nut that locks the bolts on the arm pin and link pin, then remove the arm pin and link pin, and then remove the bucket. During this process, please pay attention to the removed rocker pin and connecting rod pin not to be soiled by mud and sand, and do not damage the seal at both ends of the shaft sleeve. (3) Install the bucket or other working devices to be used. Change the position of the joystick so that the hole on the joystick is aligned with the hole on the bucket, and the hole on the connecting rod is aligned with the hole on the bucket, see the right picture. Then apply grease and install stick Pins and connecting rod pins. The installation process of the pin is reverse to the removal sequence. When installing the rocker pin, install an O-ring in the position shown in the figure below, insert the rocker pin, and then put the O-ring into the appropriate groove. When installing the connecting rod pin, first put the O-ring into the appropriate groove, and then insert the connecting rod pin. (4) Install the locking bolt and nut of each pin, and then apply grease on the pin

Product Categories : Home > Products > Working Device System > Bucket

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.